aluminium gravity die casting

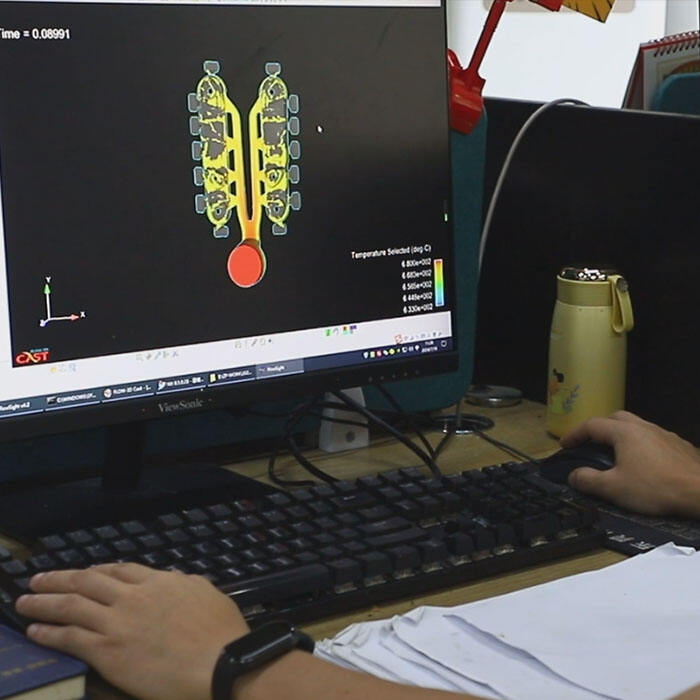

The process of gravity die casting in aluminium is a precision casting technique that makes high-precision aluminium components possible. Its biggest role is that it can produce shapes with tight tolerances and smooth surface those style requirement: Complexly complex. In addition, technology features used in this process include the use of permanent mold or die, filled with liquid aluminum alloy (under force of gravity). Gravity die casting is employed extensively in a range of industries, such as automotive, aerospace, and general engineering of lightweight and hard-wearing components made from aluminum. It process also ensures components with outstanding mechanical properties, great heat conduction performance and resistance to corrosion.