aluminum die

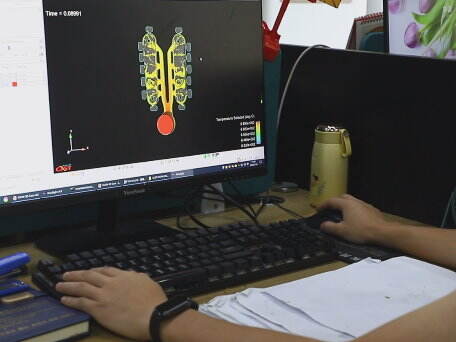

The aluminium die, a precision tool in the manufacturing industry, is used primarily for processing aluminium and other non-ferrous metals. Its functions: cutting, forming and shaping high-speed and high accuracy. In addition to cutting, forming and shaping materials Lao takes on concrete timely operations for our time It is expected that the aluminum die boasts complex geometrical designs Technological features of the aluminum die embrace complex geometrical designs, durability and resistance to wear They make it possible to produce complex parts and components consistently and reliably. Aluminum dies are used in many industries, such as automotive, aerospace, electronics and construction is essential for lightweight and durable metal components.