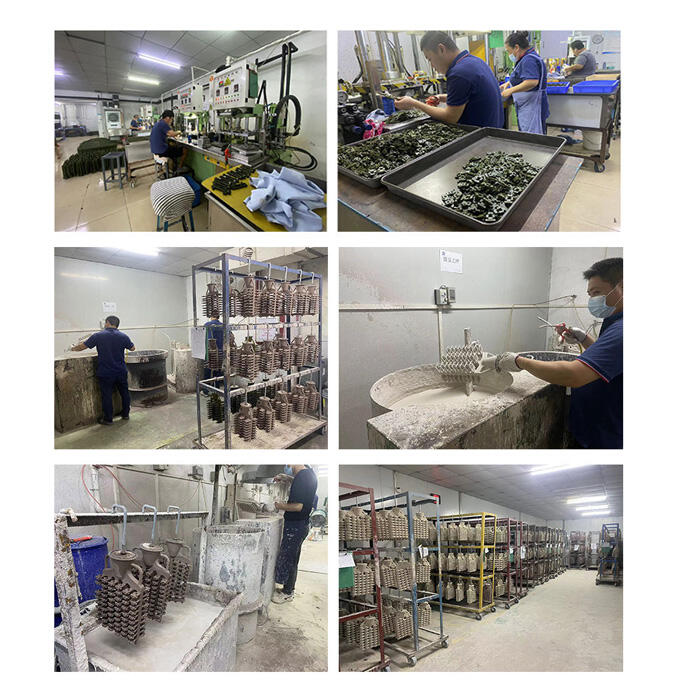

aluminum die casting parts motorcycle accessories

The parts themselves are common in motorcycle fittings. These concrete components exemplify those adjectives. Meticulous attention to detail and a rigid die casting process ensure high quality finishes beautiful details. Die-casting parts. Besides tripping the motorcycle showroom and adding extra height to your Hoof fetish, they have three main functions; they give strength to the structure of a motorcycle, help reduce weight while still offering power accessories that can be of use elsewhere thanks to their adaptability in positioning on or around the motorcycle itself. Aluminum die casting parts have a highly accurate dimensional stability, can endure higher temperatures than other materials without deformation and are more resistant against wear. From engine components, transmission parts decorative trims to structural frames of motorcycle, these accessories are essential for every aspect both function and form in the manufacture process.