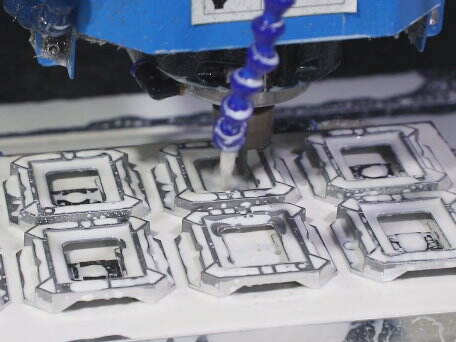

custom die cast

Custom die cast molds a very professional moulded metal product.Back to where it was for a moment: The custom die cast is of most use in making parts with fine detail and accuracy of shape. It also turns out to be easy to mass produce such components at astonishingly low cost mainly because you usually only need one set of tooling for thousands or even hundreds of thousands parts like this-so much better than machining them out one by one on a lathe! The technology in custom die casting is meant to contain metal of all sorts: aluminum, zinc and magnesium. It can also combine several components into a single piece. Among the many applications of this process, which is known for producing lightweight and strong parts.ustry"]]

This process is widely used in automotive, aerospace, electronics and many other industries where we require metal parts that are lightweight, strong and accurate.