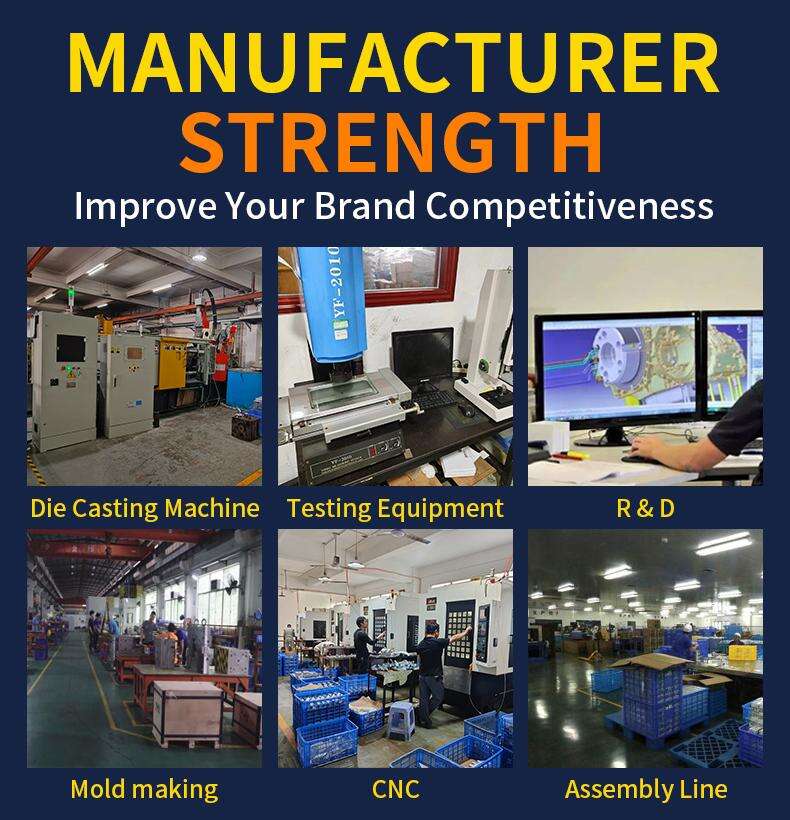

Rapid Production Turnaround

Another great thing about working with die casting suppliers is the fast production turnaround they make possible. The die casting process is highly automated, which means that it can be carried out continuously and with short periods in between. This is likely to enable customers to receive their parts quicker than would otherwise be achievable, and thus to meet tight deadlines. Moreover, customers will also be able have their products on market earlier because of longer version longitude. The high-speed operation of die casting is particularly useful for industries where production is being conducted at a fast pace and numerous components are required. By providing fast, dependable production, die casting suppliers keep their customers -and, in the case of some who are also system integrators or OEMs with brands to maintain, they themselves -ahead of competition. A quick turnaround on market requests, given the present production environment, is needed and therefore especially appreciated when manufacturing cycles are short.