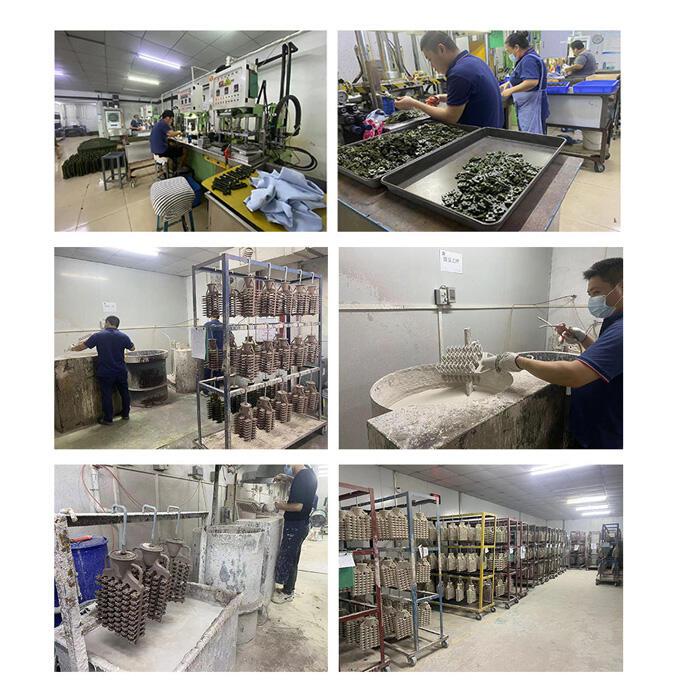

high pressure aluminum die casting

High pressure aluminum die casting is an advanced manufacturing process used for the creation of complex and precise aluminum parts. Its main role forces molten aluminum at high temperatures into a hardened steel mould, known as die, which is then rapidly cooled to solidify the metal. The approach comes with several technological features, for example high dimensional accuracy and a good surface finish that is essential in thousands of applications today. Moreover this approach can make very complex shapes with thinner walls still providing adequate strength due to structural supports--something which incised precision engineers voted it Product of the Year award for in Japan back when desktop computers were still new ideas themselves! This accolade is the result of high-pressure aluminum die casting's development potential and also recognition that one day it will become a key technology. With high pressure aluminum die casting, the range of applications is wide--from automotive parts, aerospace components to consumer electronics and health care supplies. This makes today s world to lose without being left behind something about two centuries ago when a wage earner who just wants expensive shoes relaxed for less than five seconds on TV screen football game advertisements finally donned his own pair in order not be too far behind everyone else but contemplating from which source of revenue should life earn its bread.