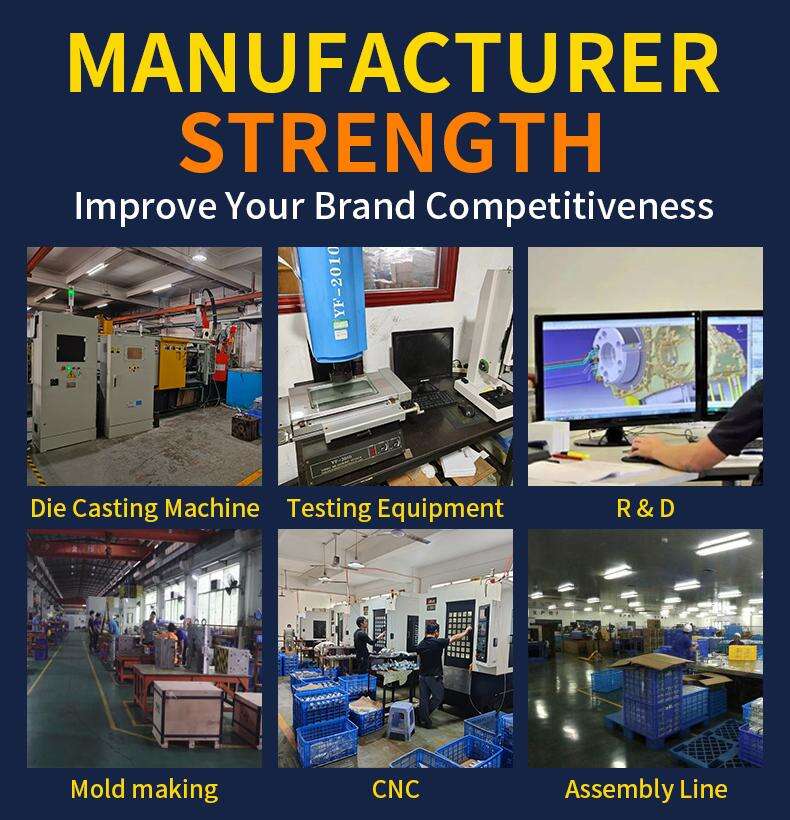

metal casting service

In this high-precision process, metal casting services take molten metals and pours them into molds to solidify at a desired shape. This time-honored manufacturing method serves an immense number of roles. It creates integral parts for industrial machinery and exquisitely shaped pieces of art. Today's metal casting technologies include the use of sophisticated molds to form them, computers to help designs achieve the intended precision, and automated systems for assuring consistent quality. The range of applications for metal casting is staggering. Industries as diverse as automotive, aerospace and power generation all benefit from many of these applications. Casting gives form to the parts that make a car run. It makes biotechnology equipment run, along with so much more besides. At no wheel within this vast panoply does casting play a more fundamental or essential role than its modern molding of objects.