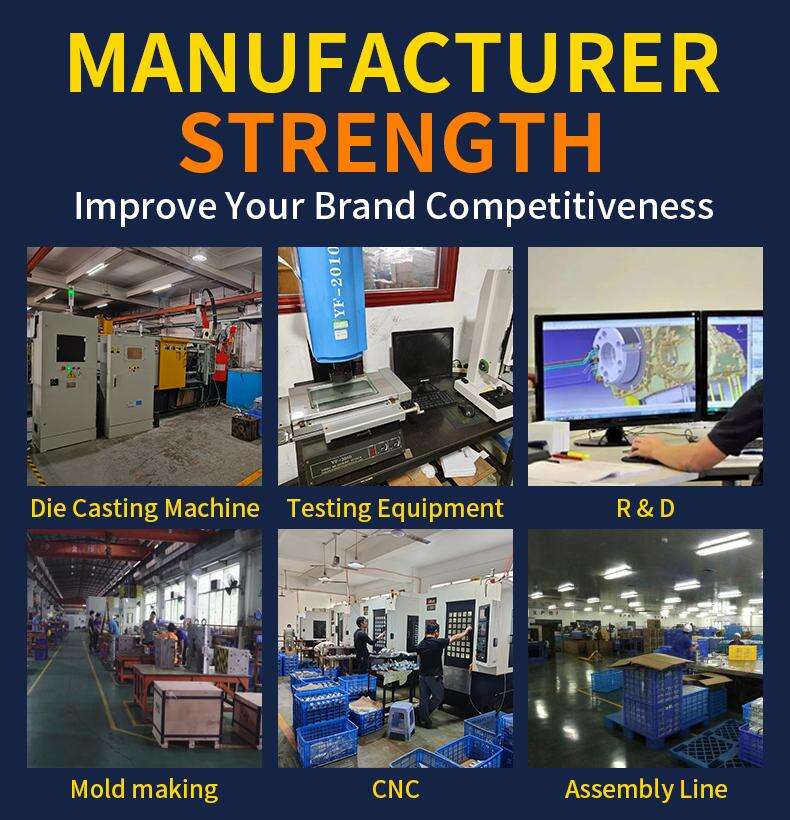

metal die casting crafts parts

Precision engineered components, the crafts parts are employed in a number of industries. They are mainly used for processing metals such as aluminium, zinc and magnesium into extremely complex components, with high precision and minimal waste. Main applications include producing complex shapes that cannot be achieved through traditional machining methods. Technological characteristics include high-pressure injection of molten metal into a mould cavity, cooling and solidification at a rapid pace as well as result in parts that are precise in dimensions and well-presentable quality. Their uses stretch from the automotive and aerospace sectors to electronics and healthcare, where durability reliability is essential.