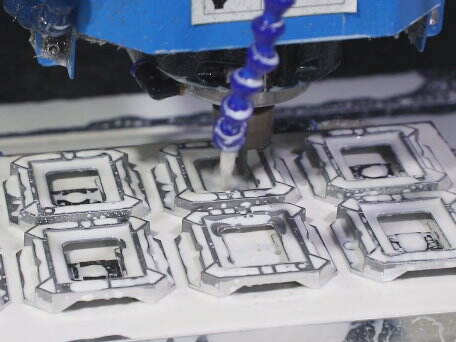

pressure die casting parts

Precision-engineered components in pressure die casting parts have a wide range of applications. Their main function is to enable the design of complex shapes, high precision and repeatability. Technological characteristics are due to the high-pressure casting systems for forcing hot liquid metal into their guide pattern steel or aluminum moulds. As a result, the parts made have excellent dimensional tolerance and surface finish. For aluminum pressure die castings are commonly used in electronics housing, chassis parts and heat sinks. These components are applied in the automotive, aerospace, and other industries that require harmonious but lightweight functional structures.