Die Casting stands out as a manufacturing process that delivers exceptional results, showcasing the advantages of Die casting. You can achieve unmatched precision and dimensional accuracy, making it ideal for creating intricate components. This method reduces production costs while maintaining consistent quality, even in large-scale operations. Its versatility allows you to work with a wide range of materials, offering tailored solutions for various applications. Industries rely on die casting to produce durable, high-performance parts that meet demanding standards. By choosing this process, you gain access to a reliable and efficient way to manufacture components with superior strength and longevity.

Understanding Die Casting

Overview of the Die Casting Process

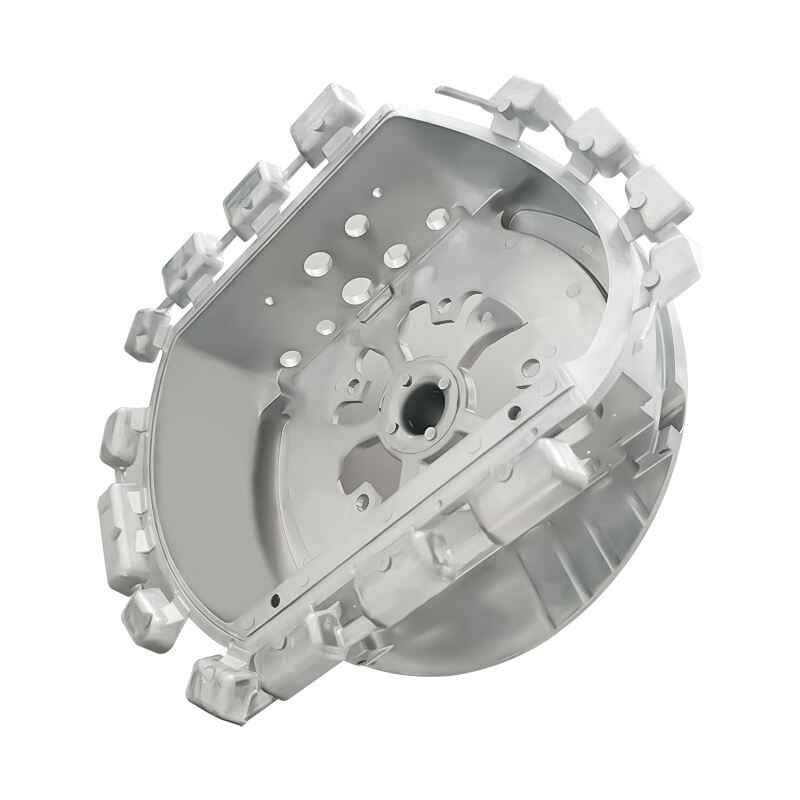

Die casting is a manufacturing process that uses molten metal to create precise and durable components. You begin by melting the chosen metal or alloy until it reaches a liquid state. This molten material is then injected into a steel mold, known as a die, under high pressure. The pressure ensures the metal fills every detail of the mold, capturing intricate shapes and designs. Once the metal cools and solidifies, you remove the finished part from the die. This process allows for rapid production and consistent results, making it ideal for industries requiring high-quality components.

The efficiency of die casting lies in its ability to produce complex shapes with minimal waste. Unlike other methods, it eliminates the need for extensive machining or finishing. You can achieve smooth surfaces and tight tolerances directly from the mold. This streamlined approach reduces production time and ensures uniformity across large batches.

Common Materials Used in Die Casting

Die casting supports a wide range of materials, giving you flexibility in choosing the right one for your application. Aluminum is one of the most popular choices due to its lightweight nature and excellent strength-to-weight ratio. It also offers high thermal conductivity and corrosion resistance, making it suitable for automotive and aerospace components.

Zinc is another commonly used material. It provides exceptional durability and allows for thinner walls in parts, which reduces material usage. Zinc alloys are ideal for creating intricate designs and are often used in consumer electronics and decorative items.

Magnesium is valued for its lightweight properties and is often used in industries where weight reduction is critical, such as aerospace and automotive. Copper and brass are also used in specific applications requiring high conductivity or aesthetic appeal. By selecting the right material, you can tailor the die casting process to meet your specific needs.

Why Die Casting is a Preferred Manufacturing Method

Die casting stands out as a preferred method due to its unique combination of precision, efficiency, and versatility. You can produce components with exceptional dimensional accuracy, ensuring they meet strict specifications. This level of precision is difficult to achieve with other manufacturing techniques.

The process also supports high-volume production without compromising quality. You can create thousands of identical parts with consistent dimensions and surface finishes. This reliability makes die casting a cost-effective solution for industries like automotive, electronics, and aerospace.

Another advantage lies in its ability to handle complex designs. You can create intricate shapes and features that would be challenging or impossible with other methods. This flexibility allows for innovative product designs and enhances the functionality of components.

Die casting also minimizes material waste, contributing to its cost-effectiveness and environmental benefits. The recyclability of materials used in die casting further supports sustainable manufacturing practices. These advantages of die casting make it a cornerstone of modern production processes.

Key Advantages of Die Casting

High Precision and Dimensional Accuracy

Ability to Produce Complex Shapes with Tight Tolerances

Die casting allows you to create intricate shapes with exceptional precision. The process uses high-pressure injection, ensuring the molten metal fills every detail of the mold. This capability makes it possible to produce components with tight tolerances that meet strict specifications. You can achieve designs that would be challenging or impossible with other manufacturing methods. This level of accuracy ensures that the final product performs reliably in its intended application.

Consistent Quality Across High-Volume Production

When you need large quantities of identical parts, die casting delivers consistent results. Each component produced maintains the same dimensions and surface finish as the others. This uniformity is critical for industries like automotive and electronics, where precision and reliability are essential. The repeatability of the process reduces the risk of defects, saving you time and resources. By choosing die casting, you ensure high-quality output even in high-volume production runs.

Cost-Effectiveness in Manufacturing

Reduced Labor Costs Through Automation

Die casting integrates automation into its processes, reducing the need for manual labor. Automated systems handle tasks like injecting molten metal, cooling, and ejecting finished parts. This efficiency minimizes human error and speeds up production. You benefit from lower labor costs while maintaining high-quality standards. Automation also allows you to scale production without significantly increasing expenses.

Economical for Large-Scale Production Runs

For large-scale manufacturing, die casting proves to be one of the most cost-effective methods. The initial investment in molds and equipment pays off when producing high volumes of parts. The process minimizes material waste, further reducing costs. You can produce thousands of components quickly and efficiently, making it an economical choice for industries requiring mass production. This advantage makes die casting a preferred option for businesses aiming to optimize their manufacturing budgets.

Material Versatility and Customization

Wide Range of Metals and Alloys Available

Die casting supports a variety of metals and alloys, giving you flexibility in material selection. Aluminum, zinc, and magnesium are popular choices due to their unique properties. Aluminum offers lightweight strength and corrosion resistance, ideal for automotive and aerospace applications. Zinc provides durability and allows for thinner walls, making it suitable for intricate designs. Magnesium’s lightweight nature makes it perfect for industries focused on weight reduction. This versatility ensures you can choose the best material for your specific needs.

Tailored Solutions for Specific Applications

The die casting process adapts to meet the requirements of different industries. You can customize molds to create components tailored to your application. Whether you need parts for automotive engines, electronic devices, or aerospace structures, die casting provides solutions that match your specifications. This adaptability ensures that the final product meets both functional and aesthetic demands. By leveraging die casting, you gain access to a manufacturing method that aligns with your unique goals.

Durability and Structural Integrity

Components with High Strength and Longevity

Die casting produces components that deliver exceptional strength and durability. The high-pressure injection process ensures the metal solidifies with a dense and uniform structure. This results in parts that can withstand heavy loads and maintain their integrity over time. You can rely on die-cast components for applications requiring long-lasting performance, such as automotive engines or industrial machinery. The inherent strength of die-cast parts reduces the risk of failure, providing you with reliable solutions for demanding environments.

The longevity of die-cast components also minimizes the need for frequent replacements. This durability translates into cost savings and improved efficiency for your operations. By choosing die casting, you invest in parts that perform consistently and endure the test of time.

Resistance to Wear, Corrosion, and Extreme Conditions

Die-cast components excel in resisting wear and corrosion. The materials used, such as aluminum and zinc alloys, naturally resist environmental factors like moisture and oxidation. This makes them ideal for outdoor or high-humidity applications. You can trust these parts to maintain their functionality even in harsh conditions.

The process also allows for the creation of parts that withstand extreme temperatures. Aluminum die-cast components, for example, perform well in high-temperature environments without losing their structural integrity. This resistance ensures that the parts remain reliable in challenging scenarios, such as aerospace or automotive applications. By leveraging die casting, you gain access to components designed to endure wear, corrosion, and extreme conditions, ensuring optimal performance in any setting.

Environmental and Sustainability Benefits

Recyclability of Materials Used in Die Casting

Die casting supports sustainable manufacturing through the recyclability of its materials. Metals like aluminum and zinc can be recycled repeatedly without losing their properties. This allows you to reduce waste and conserve natural resources. By incorporating recycled materials into the process, you contribute to a circular economy that prioritizes environmental responsibility.

Recycling also lowers production costs. Using recycled metals requires less energy compared to processing raw materials. This energy efficiency benefits both the environment and your bottom line. Choosing die casting means you adopt a manufacturing method that aligns with modern sustainability goals.

Reduced Waste Compared to Alternative Methods

Die casting generates minimal waste compared to other manufacturing techniques. The precision of the process ensures that most of the molten metal is used to create the final product. This efficiency reduces material waste and optimizes resource usage. You can achieve high-quality results without unnecessary byproducts.

The ability to reuse scrap material further enhances the sustainability of die casting. Excess metal from the process can be melted down and reintegrated into production. This reduces the environmental impact and supports cost-effective manufacturing. By selecting die casting, you embrace a method that prioritizes waste reduction and environmental stewardship.

Practical Applications of Die Casting

Automotive Industry

Engine Components and Lightweight Structural Parts

Die casting plays a vital role in the automotive industry. You can use it to produce engine components that demand high precision and durability. The process ensures that parts like cylinder heads, engine blocks, and transmission cases meet strict performance standards. These components must withstand extreme temperatures and pressures, and die casting delivers the strength and reliability required.

Lightweight structural parts are another area where die casting excels. Aluminum die-cast components reduce vehicle weight without compromising strength. This weight reduction improves fuel efficiency and enhances overall performance. You can also achieve intricate designs, such as brackets and housings, that contribute to the structural integrity of vehicles. By leveraging die casting, you gain access to high-quality parts that meet the demands of modern automotive engineering.

Consumer Electronics

Device Housings and Heat Sinks

In consumer electronics, die casting provides solutions for creating durable and precise components. Device housings made through this process offer excellent strength and a sleek finish. You can design housings for smartphones, laptops, and other gadgets with intricate details and tight tolerances. These housings not only protect internal components but also enhance the aesthetic appeal of devices.

Heat sinks are another critical application of die casting in electronics. The process allows you to produce heat sinks with complex geometries that maximize thermal conductivity. Materials like aluminum ensure efficient heat dissipation, keeping electronic devices cool and functional. Whether you need housings or heat sinks, die casting offers the precision and material versatility required for high-performance consumer electronics.

Aerospace and Defense

High-Performance, Lightweight Components

The aerospace and defense industries rely on die casting for manufacturing high-performance components. You can create lightweight parts that meet the stringent requirements of these sectors. Aluminum and magnesium die-cast components reduce the overall weight of aircraft and defense equipment, improving fuel efficiency and maneuverability.

Die casting also ensures the production of parts with exceptional strength and durability. Components like brackets, housings, and structural elements withstand extreme conditions, including high temperatures and intense mechanical stress. The process allows you to achieve complex shapes and designs, enabling innovation in aerospace and defense applications. By choosing die casting, you ensure that your components meet the highest standards of performance and reliability.

Die casting provides you with a manufacturing process that combines precision, efficiency, and sustainability. Its ability to deliver cost savings while maintaining high-quality standards makes it an essential tool for modern industries. You can rely on die casting to produce components for automotive, electronics, and aerospace applications, ensuring durability and performance. By exploring the advantages of die casting, you unlock opportunities to enhance your production processes and meet your specific needs. This method empowers you to achieve superior results in a competitive manufacturing landscape.

Table of Contents

- Understanding Die Casting

- Common Materials Used in Die Casting

- Why Die Casting is a Preferred Manufacturing Method

- Key Advantages of Die Casting

- Cost-Effectiveness in Manufacturing

- Material Versatility and Customization

- Durability and Structural Integrity

- Environmental and Sustainability Benefits

- Practical Applications of Die Casting