Die Casting Process

Die-Casting is a metal forming process that involves the use of machines, molds, and alloy materials to inject molten metal into a mold cavity under high pressure and at high speed. The metal then solidifies under pressure to form a casting. Here's a detailed explanation of the die-casting process:

Definition

Die-casting is a rapidly developing special casting method in modern metal processing technology, characterized by little or no machining. It involves filling a mold cavity with molten metal under high pressure and high speed, and allowing the metal to solidify under pressure to form the final casting.

Key Elements

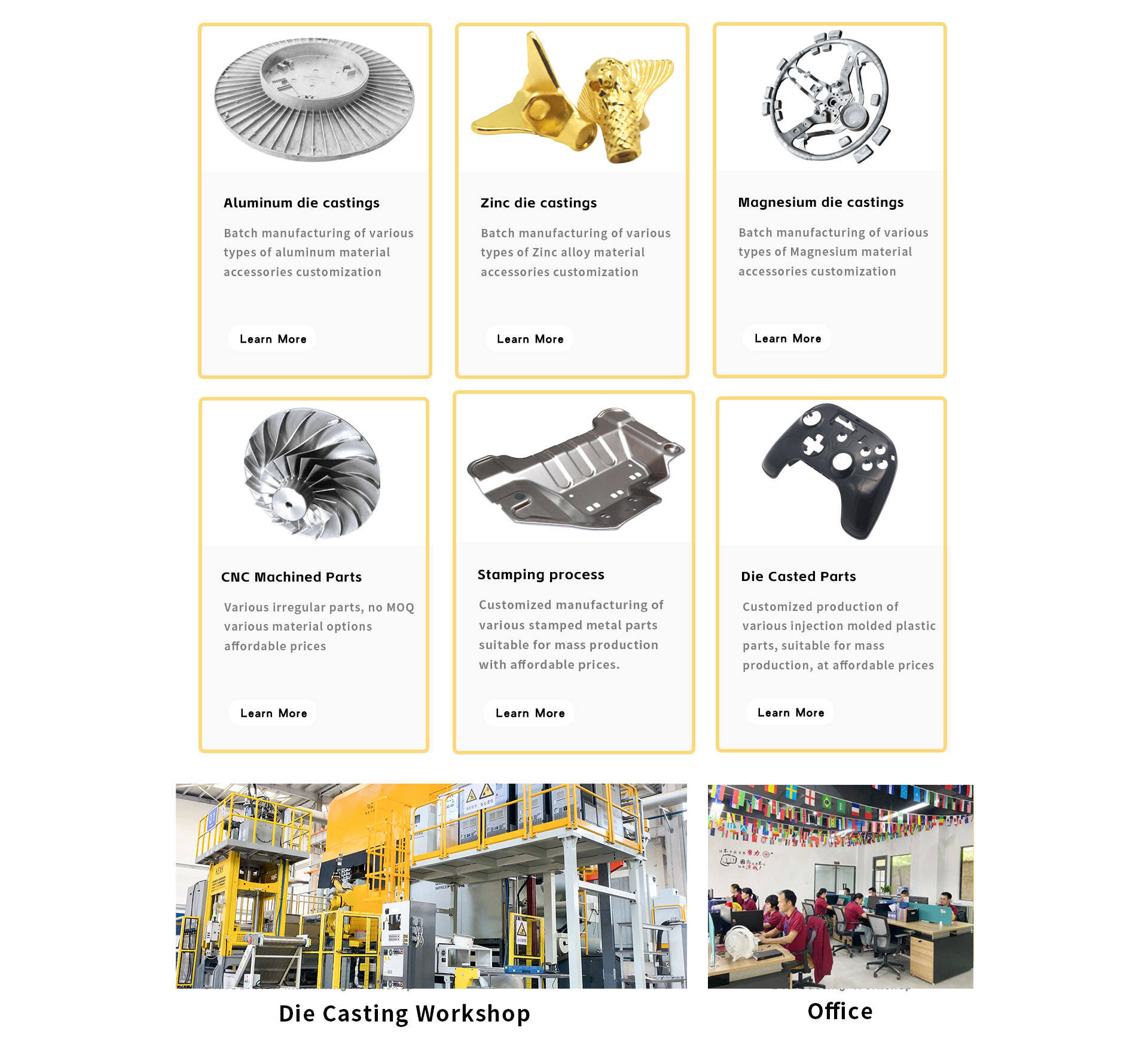

The die-casting process mainly consists of three elements: machines, molds, and alloy materials. The machine provides the necessary pressure and speed to inject the molten metal into the mold. The mold, made of high-strength materials, defines the shape and size of the final casting. Alloy materials, such as aluminum, zinc, and magnesium, are commonly used in die-casting due to their favorable casting properties.

Process Steps

Mold Preparation:

- Design and manufacture precision molds according to product requirements.

- Ensure the mold is clean and well-lubricated to facilitate the ejection of the casting.

Metal Melting:

- Melt the selected alloy material in a furnace.

- Control the melting temperature and maintain the molten metal at a stable temperature.

Injection Molding:

- Inject the molten metal into the mold cavity under high pressure and high speed.

- Ensure the metal fills the mold cavity completely and quickly.

Pressure Maintaining:

- Maintain a certain pressure after metal filling to compensate for metal shrinkage and ensure the density of the casting.

Cooling:

- Allow the molten metal to solidify in the mold under pressure.

- Control the cooling rate to ensure the quality of the casting.

Mold Opening and Casting Removal:

- Open the mold after the metal has fully solidified.

- Eject the casting from the mold.

Advantages

- High Production Efficiency: Die-casting allows for the rapid production of large quantities of identical castings.

- High Dimensional Accuracy and Surface Quality: The precision of the mold ensures that the castings have high dimensional accuracy and smooth surfaces.

- Material Savings: Die-casting requires minimal machining of the final casting, reducing material waste.

- Wide Range of Applications: Die-casting can be used to produce castings of various shapes and sizes, making it suitable for a wide range of applications.

Applications

Die-casting is widely used in various industries, including automotive, electronics, medical equipment, and more. Specific applications include engine components, transmission housings, electronic product casings, and more.In summary, die-casting is a highly efficient and versatile metal forming process that offers numerous advantages in terms of production efficiency, dimensional accuracy, surface quality, and material savings. Its wide range of applications makes it an essential part of modern manufacturing.

Why Choose DAJIN Die Casting Services

ISO Certified Aluminum Die Casting Manufacturer in China

We are proud to introduce ourselves as an ISO 9001:2015 certified aluminum die casting manufacturer in China, specializing in the production of high-quality aluminum castings and molds. Our expertise in mold making for aluminum products and alloy die casting sets us apart in the industry.

Quality Assurance and Control

Quality is our top priority. We employ a rigorous quality assurance checklist for every product we manufacture. This enables us to effectively track, examine, and verify that our aluminum castings meet the stringent standards and requirements of our clients.

Advanced Plant and Facilities

Our large aluminum casting factory is equipped with state-of-the-art die casting manufacturing machinery and up-to-date measuring instruments. This ensures that we can produce aluminum castings with the highest level of accuracy and efficiency.

OEM Capabilities

We understand that every business has unique needs. Our aluminum casting service is fully capable of realizing complex designs and producing custom aluminum castings with specific configurations. Our OEM capacity allows us to tailor our products to meet the specific requirements of our clients.

High Productivity and Efficiency

We have reliable raw material supplies and a team of highly trained staff who work tirelessly to ensure that aluminum die casting parts are manufactured with high efficiency. We guarantee that your order will be delivered within the promised period, without compromising on quality.

Economical Pricing

Aluminum is an economical metal casting option, and we further reduce costs by implementing effective cost control measures throughout the production process. This allows us to offer aluminum casting parts at prices that are lower than those of other aluminum castings manufacturers, without sacrificing quality.