casting auto parts processing service

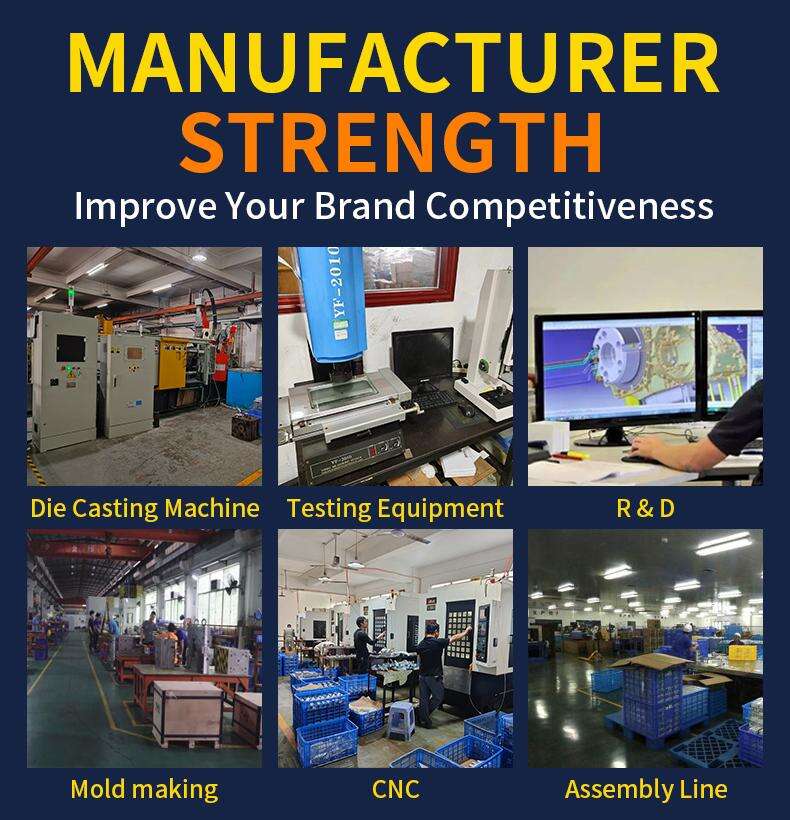

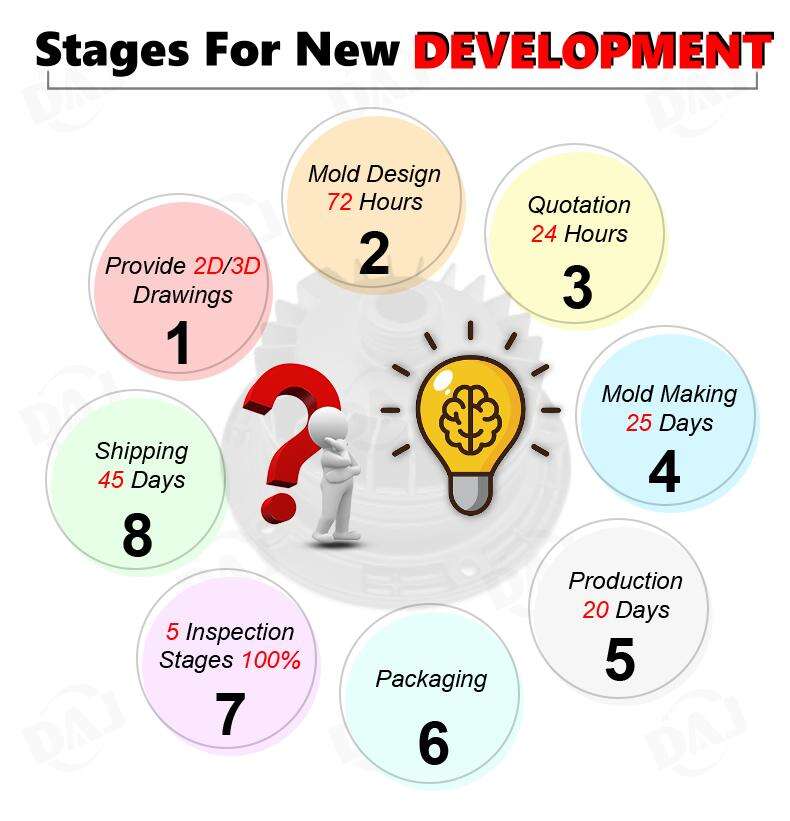

In the casting auto parts processing service, a full industrial process is engaged by which liquid metal is transformed into high-quality, precision automotive parts. Comprising advanced casting technologies, the service performs such essential functions molding disposal,fusion and molding cooling prova essed front finish treatment and packing for shipment. Technological features include the utilization of computer-aided design (CAD) to ensure that crafts molds with precision, automated pouring systems for uniformity of product quality, and strict quality control measures throughout the process. The applications of casting auto parts processing are diverse, ranging from the manufacture of engine components and transmission gearcase parts to the car body stiffness that require almost all forms. This service produces auto parts that are designed to meet the stringent industry standards, thereby offering efficiency and economy in supply chain.