Aluminum die casting often faces challenges due to common defects. These flaws can reduce product quality, increase costs, and disrupt efficiency. You must identify and address these issues early to avoid complications. Proactive measures, such as pr...

VIEW MORE

Choosing the right aluminum alloy for die casting ensures your product performs well and lasts longer. Each alloy offers unique properties, so you must evaluate factors to consider, such as strength, corrosion resistance, and cost. These choices dire...

VIEW MORE

Aluminum die casting parts require proper surface treatments to perform well in demanding environments. These treatments improve durability, resist corrosion, and enhance visual appeal. In 2025, advancements in technology offer innovative solutions t...

VIEW MORE

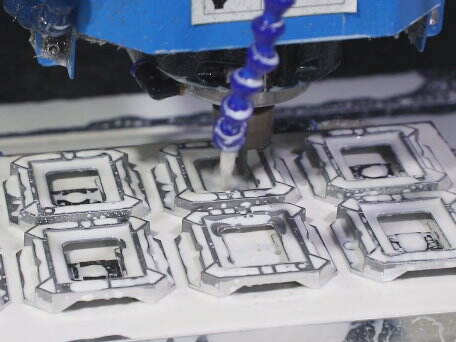

Introduction Aluminum die casting parts play a vital role in shaping modern industries. You benefit from their lightweight structure, exceptional durability, and cost-efficiency. These qualities make them indispensable in producing precise components...

VIEW MORE

Introduction The choice of zinc alloy plays a vital role in shaping the detail and complexity of die cast parts. Zinc alloys offer unique properties like excellent fluidity, high mechanical strength, and superior thermal conductivity. These character...

VIEW MORE

Introduction Reducing defects in zinc alloy die casting plays a vital role in ensuring high-quality products. Defects can lead to wasted materials, increased costs, and compromised performance. By addressing these issues, you can enhance the efficien...

VIEW MORE

Introduction The design of a part plays a crucial role in zinc alloy die casting. It determines how efficiently the process runs and directly impacts the quality of the final product. When you make thoughtful design choices, you can reduce manufactur...

VIEW MORE

Aluminum material stands out as a top choice for die casting due to its exceptional properties. Its lightweight nature makes it ideal for applications where reducing weight is crucial. The impressive strength-to-weight ratio ensures durability withou...

VIEW MORE

Introduction Zinc alloy is widely specified for die casting because there is no other plastic production material with specific properties. But even when choosing a material for die casting, assessing mechanical properties per the requirements of the...

VIEW MORE

Introduction The process of die casting for zinc alloy can obtain precision zinc die casting parts. We can plate or coat these parts for property enhancement or decoration. In this article, we will to see the how can zinc alloy die casting parts be p...

VIEW MORE

Introduction Due to this feature, Zinc alloy die casting renders the center point manufacturing of our modern items for the car and electronic enterprise. Zinc alloy is characterized by high strength, durability, and precision, allowing for a wide ra...

VIEW MORE

Introduction It is important that die cast metals have corrosion resistance, both to improve the life of the die casting and to enhance the performance of the part. The most commonly used materials for die casting are zinc alloy, aluminum, and brass,...

VIEW MORE